Home / Products / Flux / How it works

back to main page

back to main page

The explanation of how electro magnetic radio waves can prevent the build up of yeast and allow monthly beer line cleaning is fairly complicated, although we have provided a detailed explanation below.

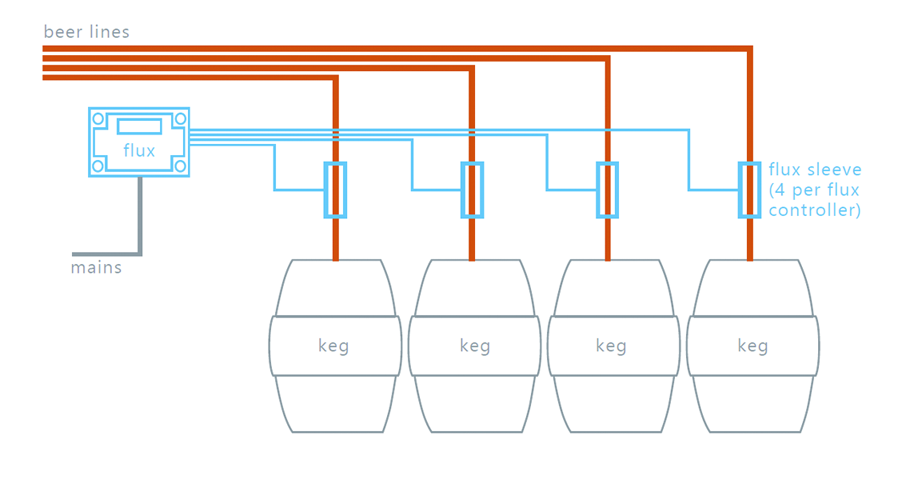

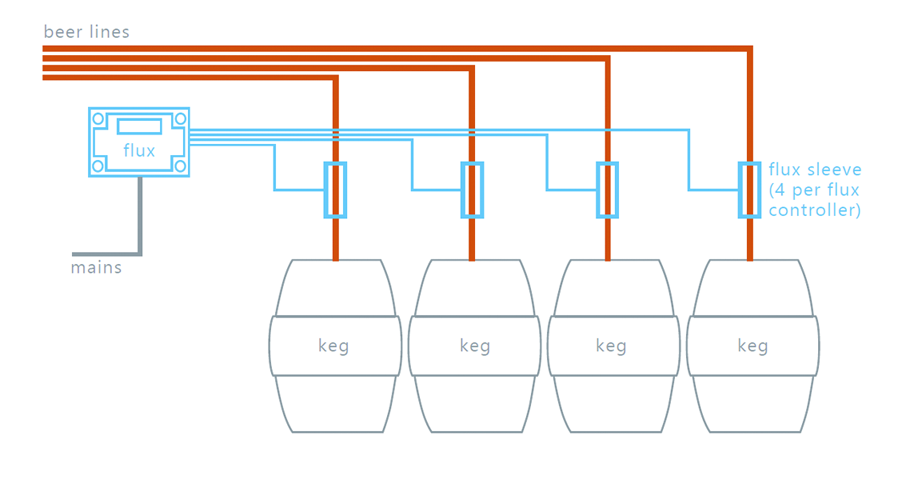

The Flux unit emits a series of induced magnetic pulses, via the computerised printed circuit board.

Although the precise mechanism by which dissolved free yeast is nucleated into a precipitated particle is not known, it is probable the induced magnetic pulses presented through the beer create an atomic electrochemical imbalance which causes alignment and attraction of the free yeast molecules in solution during the magnetic pulses. In such circumstances, due to the relatively low conductivity of yeast, the agglomeration of free yeast into a particle is facilitated by a relatively slow electrical charge flow retaining the respective atoms together. Subsequently, the yeast particles are slightly charged, either negatively or positively and so have an inherent reluctance to disassociate.

The application of magnetic pulsing additionally creates ultrasonic acoustic cavitation and de-agglomeration within the volume of liquid, in this instance mainly beer or cider, to create thousands of cavitation bubbles. These cavitation bubbles are initially nucleated and then expand to a nacent size and then collapse with sufficient energy to mechanically weaken or disrupt bacteria or biological cells. This sonication will significantly improve biocidal action.

The electro magnetic radio waves emitted from the Flux unit vary through eight different frequencies, all in the range 1.6 to 6.8 KHz. These are presented in a manner whereby the frequency is ramped, in discrete frequency shifts, over fixed time periods through the predetermined time period in order to facilitate greater yeast agglomeration action. Normally, each frequency harmonic is initiated by an initiation spike of enhanced magnetic strength. These are ramped from a base frequency level, through a predetermined time period, in an eight phase cycle. This cycle of radio/ ultrasound pulses creates the optimum conditions to prevent cell clustering and is the vital element of the Flux patent.

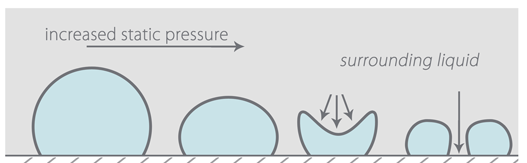

The process of cavitation is an integral factor within the mode of operation of the Flux system.

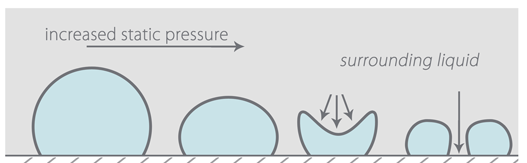

The Flux system utilises electro magnetic radiation to stimulate the process of cavitation, the rapid formation and collapse of millions of tiny bubbles, or cavities, which grow during the low pressure phase and then compress and implode during the high pressure phase of the sound wave.

These implosions create surges of energy or ‘shock waves’ which in turn stimulates de-agglomeration, the breaking down of clumps of particles.

De-agglomeration is described as the process of breaking up or dispersing that which has clustered together.

In the Flux application the entire process of cavitation/ de-agglomeration prevents the clumping of yeast particles, therefore preventing them from sticking to the beer lines.

Beer quality is maintained and often enhanced. Also beer lines remain cleaner for longer, allowing cleaning frequency to be reduced from weekly to monthly beer line cleaning.

Please complete this section for more information

|

Any questions? info@elementaleu.com |

|

Call Us +44 77 9855 7733 |